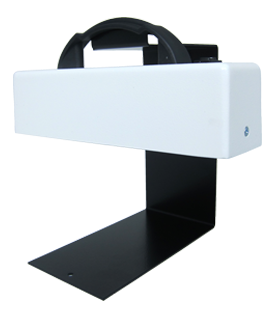

Direct insertion or bypass designs

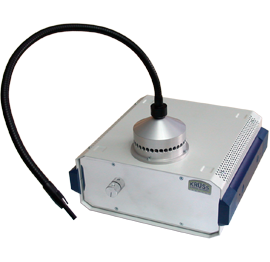

Krüss offers two models of Process Refractometers in thePR21 series. The PR21 has been developed for direct insertion into pipes and boilers, for process monitoring, control and separation of products in such industries as chemicals, beverages, food, pulp, paper, and sugar. Installation in a pipeline or tank is simple, as no bypass is necessary. Three interfaces are available for this unit: Analogue 0/4-20 mA, Ethernet, or PROFIBUS.

The PRB21 is a basic bypass process refractometer, meeting all requirements in continuous process monitoring, filling the gap between the DR6000 series of digital laboratory refractometers and the PR21. It is cost-effective, easy to install, has a wide measurement range, and like the PR21 covers a large range of industry applications. RS-232 and analogue 0/4–20 mA interfaces are available for this unit, and PROFIBUS can be supplied upon request. For visual monitoring an optional display is also available.

For prices and availability information on the PR21 series of Process Refractometers, please contact your nearest Krüss distributor, who will be delighted to help.

![]() For full technical specifications, please download the brochure here.

For full technical specifications, please download the brochure here.

Why use Refractometers in pipelines?

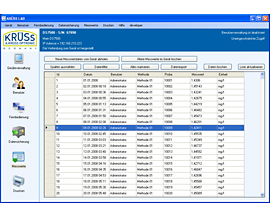

The monitoring of refractive index is a popular method of inline quality control in many process industries, including pulp and paper, food and beverage, chemical and pharmaceutical, and wastewater. It provides real-time data for quality control and Good Manufacturing Practice (GMP), and can be used to monitor qualities such as concentration of a solution, density of a fluid, or % Brix.

An inline process refractometer is installed directly into pipework or a boiler, with standard connections for easy assembly. The alternative bypass process refractometer analyses a stream of fluid drawn off the main process run.