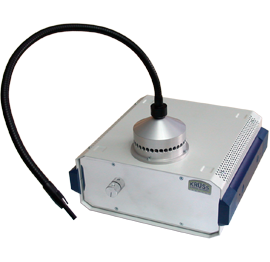

Compact, sturdy and simple to use

Krüss offers over twenty models in the HR series of Manual Handheld Refractometers, designed for the determination of mixing ratios, quality and quantity inspection applications within a large range of industries. The HR range has been designed for quick daily usage. It is compact, sturdy and simple to use, measurements are easily read, and is suitable for most applications because of the various scales and functions. For calibration either distilled water or a small calibration plate is employed, depending upon model. The HR is supplied in a case, complete with conversion tables.

For prices and availability information on the HR series of Manual Handheld Refractometers, please contact your nearest Krüss distributor, who will be delighted to help.

![]() For full technical specifications, please download the brochure here.

For full technical specifications, please download the brochure here.

Refractometers: a technical background

Refraction is a commonly observed phenomenon, often seen when a spoon or straw appears to bend in a glass of water. What is being witnessed is a demonstration of the different speeds at which light travels through different media.

It is well known that the speed of light is the universe’s upper speed limit. In a vacuum, light travels at almost 300,000km per second. What may be less well appreciated is just how much light will be slowed down when travelling through a denser medium. Air makes only a small difference – the speed is slowed by only about 90km per second – while typical glass will slow the speed of light by a third, to around 200,000km per second.

The ratio between the speed of light in a vacuum, known as c, and the speed in the medium being examined, is the refractive index or index of refraction. In the case of air, with its tiny effect on c, the refractive index is close to 1 (actually it is about 1.0003). Glass has a refractive index – the abbreviation nD is commonly used – of about 1.5. A refractive index is always greater than 1.

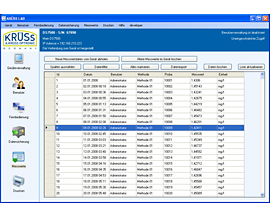

Measurement of the refractive index of a material yields valuable information about its composition, especially when other known factors are taken into account. In an industrial process, it is quite straightforward to continuously monitor nD and use this to assess the concentration of a solution or the percentage of solids being carried. As an example, at 20C a sample of pure water will have a refractive index of 1.33, while a 40 Brix solution of sugar and water will have a refractive index of 1.39986. The rate of change of refractive index with temperature helps the analyst to pinpoint the exact composition of the sample.

In gemmology, the identity of a gemstone and its value can be assessed by measuring its refractive index. In winemaking, Oechsle values are easily found through use of an appropriate refractometer. In many industrial processes, the simple spoon-bending effect seen in a glass of water provides a powerful analytical tool.