Hổ trợ trực tuyến

|

|

|

0902337066 0902337066

|

|

Ms Diệu : dieu.ans@ansvietnam.com |

|

Menu sản phẩm

Ứng dụng

Hãng sản xuất

Lượt truy cập

|

Đang online | 72 |

|

Lượt truy cập | 7456219 |

Mark 10 Vietnam - ISO 594 Luer Lock Torque Tester

Loại sản phẩm: Testers

Mã sản phẩm: ISO 594 Luer Lock Torque Tester

Nhà cung cấp: Anh Nghi Sơn

Xuất Xứ: chính hãng

Hãng sản xuất: Mark 10

Giá : Vui lòng liên hệ

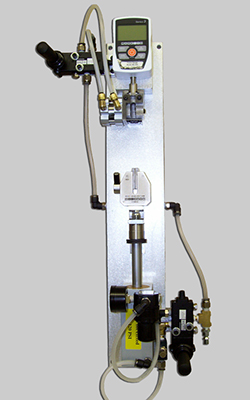

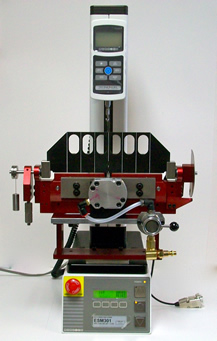

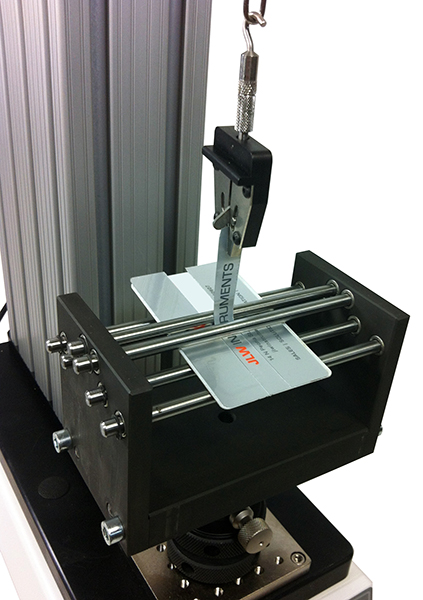

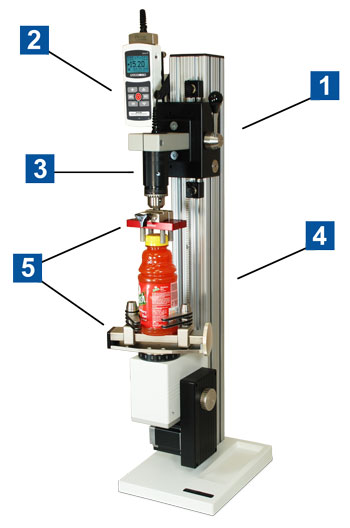

ISO 594 Test Assembly Machine is Needed for Valid Test Results.

|

|

|

ISO 594 Specifies Very Light Torque and Force Requirements. ISO 594 Specifies Specific Values which are Verifiable. ISO 594 Requires Simultaneous Application of Both Force and Torque. Variation in Test Results Create Test Disputes. How to Correctly Make the ISO Luer Test Piece/Reference Fitting Assembly. If the requirement is only to have a few pieces tested, a limited testing requirement, we can make a referral to a laboratory which will make the ISO Luer Test Piece/Reference Fitting assembly in full accordance with the ISO 594 Luer standard. Citations from ISO 594: Conical fittings with 6% (Luer) taper for syringes, needles and certain other medical equipment. ISO 594/1 pp 5.2.1 ISO 594/1 pp 5.3.1.1 ISO 594/1 pp 5.5.1 ISO 594/1 Annex A.2 ISO 594/2 pp 5.2.1 ISO 594/2 pp 5.3.2.1 ISO 594/2 pp 5.6 ISO 594/2 pp 5.8.1 Initial Publication: May 6, 2009 |

|

Sản phẩm liên quan

Hans schmidt Vietnam - Ya ...

Hans schmidt Vietnam - Ya ...

Hans schmidt Vietnam - Ya ...

Hans schmidt Vietnam - Ya ...

Hans schmidt Vietnam - Ya ...

Hans schmidt Vietnam - Ya ...

Hans schmidt Vietnam - Ha ...

Mark 10 Vietnam - Cap Tor ...

Mark 10 Vietnam - Torque ...

Mark 10 Vietnam - TAPPI T ...

Mark 10 Vietnam - TAPPI T ...

Mark 10 Vietnam - Spot We ...

Mark 10 Vietnam - Pneumat ...

TAPPI T577 Score Bend Te ...

Mark 10 Vietnam - ISO / I ...

Mark 10 Vietnam - Compres ...

Mark 10 Vietnam - Pull Te ...

Mark 10 Vietnam - Torque ...

Mark 10 Vietnam - Peel Te ...

Mark 10 Vietnam - Spring ...

Mark 10 Vietnam - Tensile ...

Mark 10 Vietnam - Model W ...

Mark 10 Vietnam - Model W ...